Orbex has publicly unveiled the company’s Prime rocket for the first time at the opening of the firm’s new headquarters and rocket design facility in Forres in the Scottish Highlands.

The rocket is designed to deliver smallsats into Earth’s orbit — the rocket was unveiled at an opening ceremony attended by VIPs from the UK and European space community as well as local community stakeholders.

Artistic rendition of the Orbex rocket in flight. Image is courtesy of the company.

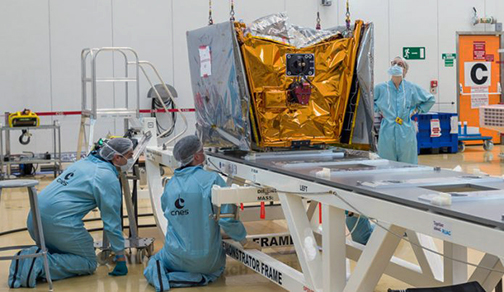

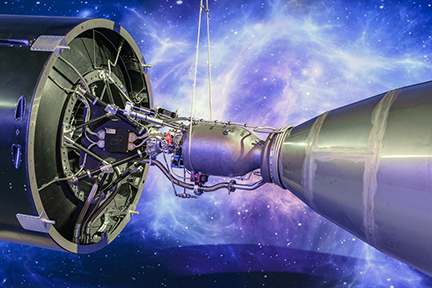

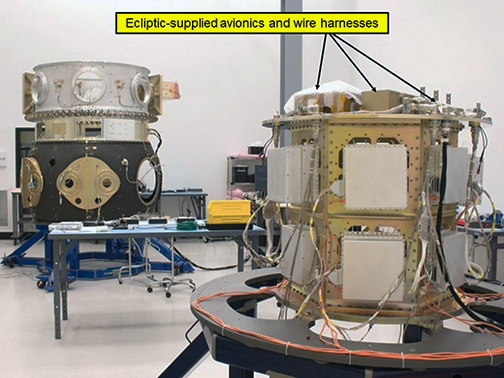

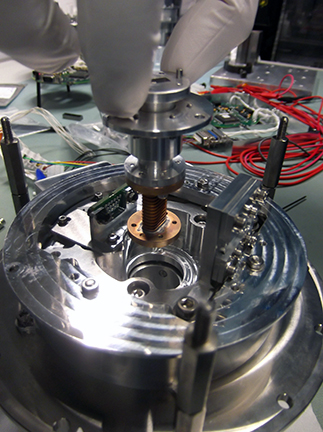

The completed engineering prototype of the Stage 2 rocket (the stage that will transit into orbital flight after launch) is made from a specially-formulated, lightweight, carbon fiber and aluminum composite and includes the world’s largest 3-D printed rocket engine.

Artistic rendition of the Orbex rocket engine in space. Image is courtesy of the company.

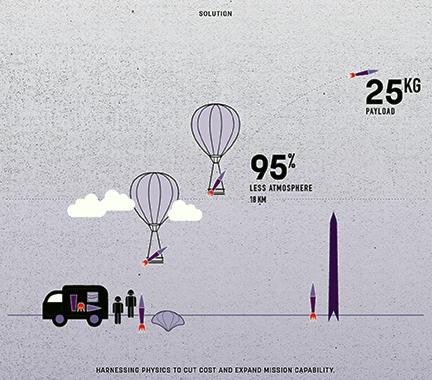

Orbex Prime is a completely re-thought and re-engineered two-stage rocket, designed by Orbex aerospace engineers with professional experience from organizations that include NASA, ESA and Ariane, as well as other commercial spaceflight companies. According to the company, Prime launchers are as much as 30 percent lighter and 20 percent more efficient than any other vehicle in the small launcher category, packing more power per cubic liter than many heavy launchers.

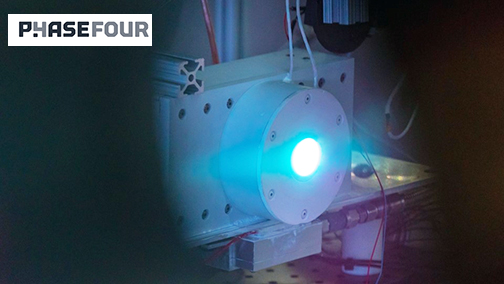

Seen for the first time, the 3-D printed rocket engine was uniquely manufactured in a single piece without joins in partnership with additive manufacturer SLM Solutions. Given the extreme temperature and pressure fluctuations involved in space flight, this gives the engine an advantage over other rocket engines, which can suffer from weaknesses associated with joining and welding. This is also the first commercial rocket engine designed to work with bio-propane, a clean-burning, renewable fuel source that cuts carbon emissions by 90 percent compared to fossil hydrocarbon fuels, supplied by Orbex’s new exclusive BioLPG fuel partner, Calor.

Orbex first came into the public eye in July of 2018, when the UK Space Agency announced that Orbex had been selected to launch from the proposed spaceport in Sutherland in the Scottish Highlands, as part of the main consortium. At that time, the company announced that it had already won £30 million ($40 million) in private and public backing for the project, making it Europe’s best-funded private launch company, straight out of stealth mode.

The company revealed the identities of more customers that would be among the first to launch their satellites from the Sutherland spaceport. On Orbex Prime’s maiden flight from Scotland in 2021, the rocket will carry an experimental payload from UK-based Surrey Satellite Technology Ltd. (SSTL), the world’s leading manufacturer of smallsats. This launch will represent an important first for the UK commercial space industry, demonstrating the UK’s end-to-end launch capability with a UK rocket launching a UK satellite from a UK spaceport.

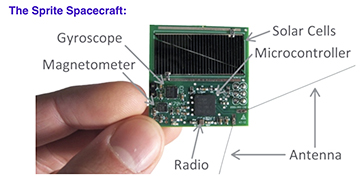

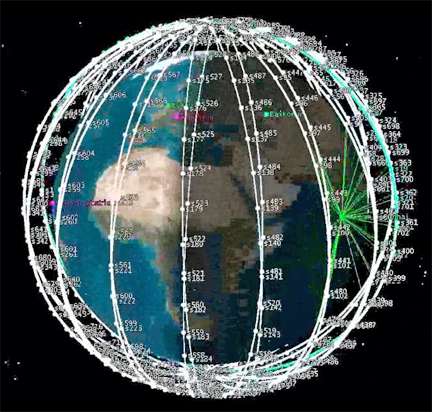

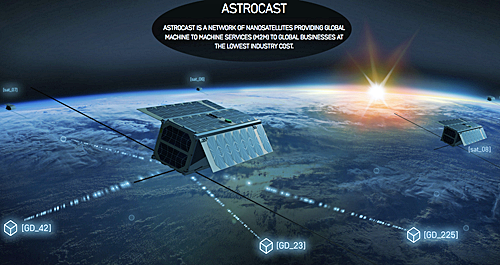

Orbex also announced that Swiss-based Astrocast SA, has selected Orbex to launch multiple nanosatellites for the development of a planet-wide Internet of Things (IoT) network. Astrocast’s satellite-based IoT network will eventually include 64 smallsats, spread across eight strata above the Earth to deliver IoT connectivity across the planet, including regions currently considered remote or inaccessible. One of the leading companies in the European space sector and strategic investor in Orbex, Elecnor Deimos, has also confirmed that it has contracted with Orbex for as many as 20 satellite launches.

The new Headquarters building at Forres is a 2,000 square meter facility and will combine a rocket design and integration facility, an operations center as well as executive offices. It is expected that the facility will help to bring more than 130 jobs to the Scottish Highlands region, with an intense recruitment drive for the company already underway.

Executive Comments

Business Secretary Greg Clark said that the plans for a spaceport in Sutherland have already attracted significant investment, and Orbex’s rocket design facility will bring more than 100 new jobs to the Scottish Highlands region. The space sector is a great British success story — new innovations, capabilities and expertise are driving significant growth, with the sector generating close to £15 billion in income each year.

Graham Turnock, Chief Executive, UK Space Agency, noted that Orbex’s new rocket design facility brings Britain one step closer to having its own domestic commercial launch capability and firmly positions the UK as Europe’s front-runner for those looking to Earth’s orbit and beyond for new opportunities. The new facility and future spaceport operations will help unlock vast economic and societal benefits not just in Scotland, but directly across the UK.

Chris Larmour, Orbex CEO, added that since the announcement in July 2018 that the company had been selected to launch from the Sutherland spaceport, Orbex has been on an incredible journey, largely behind-the scenes. We can now publicly reveal the company’s technical and commercial momentum. Not only does the company have a full engineering prototype of the complete Stage 2 of the Prime rocket, but also a growing roster of customers hoping to be among the first to launch satellites from Scotland. There are only a handful of private launcher companies globally that have practical experience in the design and production of micro-launch vehicles, and even fewer that have combined those skills with sufficient funding and the commercial contracts to execute on their plans. Orbex is looking forward to the next steps in the company’s development from the firm’s new home in Scotland.