Rocket Lab will open a new facility in Long Beach, California, that will serve as the firm’s Corporate Headquarters, provide incremental production capacity as well as Mission Control Center capabilities.

Construction on Rocket Lab’s Long Beach Complex has begun, with the facility scheduled for completion in the second quarter of 2020. The Complex has been designed to produce more than 12 full Electron launch vehicles each year to support a monthly launch cadence from Rocket Lab’s first U.S. launch site, Launch Complex 2 in Wallops Island, Virginia. Production facilities for Rocket Lab’s flagship Rutherford engine will also be expanded, with the company planning to produce more than 150 engines for the Electron launch vehicle in 2020.

Artistic rendition of Rocket Lab’s new Huntington Beach HQ.

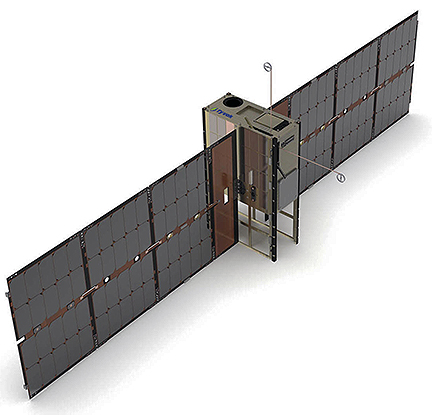

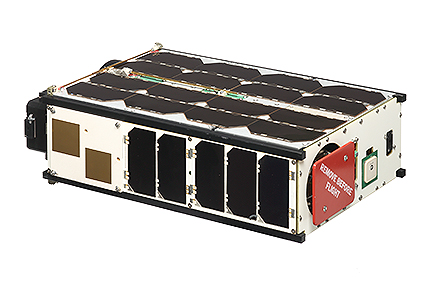

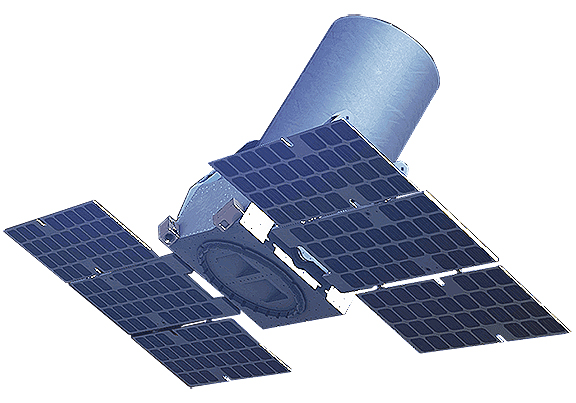

Rocket Lab’s rapidly growing satellite manufacturing capabilities are a key driver behind the new Long Beach complex. In 2019 the company expanded beyond launch services and began designing and manufacturing Rocket Lab satellites to provide an end-to-end mission service. Based on flight-proven technology employed in the Electron Kick Stage, Rocket Lab satellites are a complete spacecraft solution for a range of LEO and Lunar orbit missions, from constellation development, through to technology demonstrations and hosted payloads. The new Long Beach complex will support end-to-end production and testing of Rocket Lab satellites, with the first satellites booked to launch on Electron from Q3 2020.

Rocket Lab’s first U.S-based Mission Control Center will also be located at the Long Beach Complex. By operating two launch sites and two Mission Control Centers, Rocket Lab can conduct simultaneous launches from Launch Complexes 1 and 2 to meet the growing need for responsive space launch.

Rocket Lab Founder and CEO, Peter Beck, stated that the new Long Beach Complex will mean larger production facilities, purpose-built customer experience areas and room to grow as the company enters another busy launch year. He said that as the company enters their third year of orbital launches and expand into satellite manufacturing, Rocket Lab is investing in major infrastructure and growing the team to provide frequent and reliable access to orbit for small satellites. Long Beach is an ideal location for the team; it has a vibrant space community, it’s close to many of the firm’s suppliers and offers room to grow. The City of Long Beach has been incredibly welcoming and we look forward to working with them to continue growing the local space economy.

There are currently more than 50 roles open for positions at the new Long Beach Complex, including positions in engineering, avionics production, Mission Management, Launch Services and more.